Precision Supply Chain Operations™

Current State of Mediocrity

As the temporary boost from the COVID-19 bubble fades, many organizations are confronting the harsh reality of their true performance. An inability to manage labor challenges, an overreliance on automation as a panacea, and the persistence of outdated structures and processes have caused mediocrity to become the accepted norm.

- 93% of supply chain executives acknowledge that to remain successful, they must adapt their operations to be more flexible, agile, and resilient. Even those performing well today recognize the need for urgent change.

- Over the past five years, product delivery times have increased by 20% on average, accompanied by rising operational costs. This troubling trend underscores how current strategies are failing to keep up with market demands.

Current State of Mediocrity

Supply chain operational performance is critical to customer experience and organizational success. However, as the temporary boost from the COVID-19 bubble fades, many organizations are confronting the stark reality of their actual performance. Unfortunately, external pressures and internal barriers have resulted in mediocrity becoming the accepted industry standard.

- 93% of supply chain executives acknowledge that to remain successful, they must adapt their operations to be more flexible, agile, and resilient. Even those performing well today recognize the need for urgent change.

- Over the past five years, product delivery times have increased by 20% on average, accompanied by rising operational costs. This troubling trend underscores how current strategies are failing to keep up with market demands.

The forces pulling organizations into mediocrity are clear:

- 76% of supply chain leaders face labor challenges, leading to over-reliance on temporary workers and lower-quality talent, fostering risk-averse management that avoids meaningful change.

- 50% of businesses have increased spending on supply chain technology, but 69% report disappointing results. Rapid technological change has created confusion, leaving organizations lost in the hype.

- Most organizations lack a performance culture. Short-term planning, cost-cutting that stifles innovation, and rewards focused on tactical wins reinforce a mindset that accepts the status quo rather than challenging it.

- Organizational structures are siloed, and staff have constrained experience. Few have a full operational view or design experience. Career development is often neglected.

Think Differently,

Solve The Performance Paradox

Nobody wants mediocrity, yet many organizations remain trapped in the Performance Paradox—the inability to drive real, sustainable change. This issue stems from fundamental disconnects in the current operating model, which allows and even promotes:

- Siloed thinking, ignoring the interdependencies in supply chain operations.

- Skill and competency gaps, with no clear strategy for leadership or staff development.

- Inadequate measurements and an absence of comparative benchmarking.

The Performance Paradox is most evident in organizations clinging to an underperforming status quo, either lacking the insight to recognize what “good” looks like or fearing that any change might make things worse.

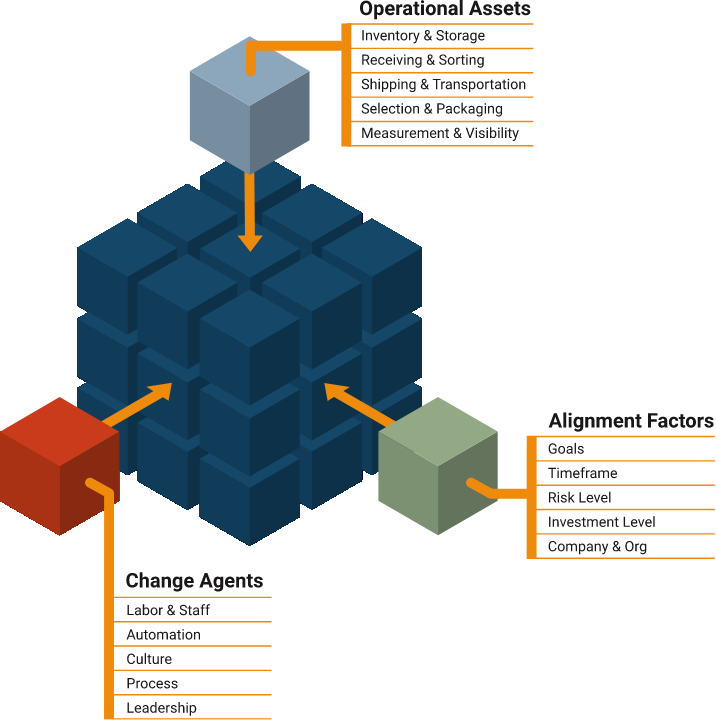

To break free from mediocrity, organizations must think differently and challenge the status quo. Success hinges on managing supply chain operations as an interconnected system, balancing key factors across three critical dimensions—Operational Domains, Change Agents, and Strategic Alignments.

Consequences

“The average tenure of supply chain executives continues to shrink as leaders struggle to deliver the performance improvements their organizations demand.”

“High-performing employees often burn out quickly, frustrated by a culture that rewards maintaining the status quo over pursuing meaningful improvements.”

“Talented individuals in the organization have few opportunities for growth or mentorship, as development programs take a backseat to short-term firefighting.”

![]() Rigorous Execution

Rigorous Execution

Achieving high standards and consistent results comes from focusing on every detail.

![]() Innovative Thinking

Innovative Thinking

Game-changing performance is driven by fresh ideas and looking beyond traditional approaches.

![]() Holistic Planning

Holistic Planning

Effective solutions take the big picture into account, ensuring all elements work together for lasting impact.

![]() Practical Decision-Making

Practical Decision-Making

Decisions need to be realistic and in sync with the organization’s core values, budget, and priorities.

New Way: Precision Supply Chain Operations

Supply chain organizations need more than incremental improvements—they need a fresh, dynamic approach that elevates service levels while reducing costs. This demands a clear vision of excellence, a willingness to challenge the status quo, and a commitment to continuous innovation. At Brecham Group, we’ve developed a proven approach through years of hands-on experience across thousands of distribution centers. We call it Precision Supply Chain Operations.

Operations are deeply interconnected, making linear, isolated thinking problematic. Precision Supply Chain Operations equips operators to think, plan, and execute through and across critical dimensions: change agents, operational domains, and strategic alignments.

Brecham Group solutions bring Precision Supply Chain Operations to life by delivering immediate, measurable value, enabling your team for long term success, and guiding your unique “precision journey”. Our solutions are delivered through our Brecham Group Success Model, and are built upon a system of strategic consulting engagements, development workshops, training classes, platform tools, and staff augmentation offerings.

“Every time Brecham Group completes a project, we reduce costs by 10%”

-Dan Renehan

President, Stone Wheel

Let’s Connect

Meet with a Brecham Group Managing Director to discuss your Precision Supply Chain Operations journey.